|

|

|

|

|

|

NO BAKE MOULDING |

|

| |

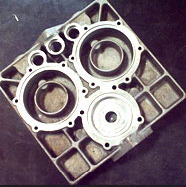

No Bake is a casting process that uses chemical binders to bond the molding sand. The sand is then transported to the mold fill station in preparation for filling of the mold. A mixer is then used to blend sand with the chemical binder and the catalyst. When the sand exits the mixer, the binder begins the hardening process. After the compaction process, a rollover process is used to remove the mold from the pattern box. The mould is then readied for handling the molten metal. After a shakeout process, the molded sand is taken away from the casting. Then various procedures follow including the finishing and the sand can be reclaimed by thermal means. |

|

|

|

| |

The chemical nature of the binders makes this a highly specialized process that has to been handled with considerable expertise and knowledge. At VJP, we have developed our expertise in the process over the years and today are able to harness the potential of the process to create casts of the highest quality and to a great degree of accuracy.

Features

- Chemical binders are used to create high strength moulds.

- When the temperature is brought to normal levels, the molds turn rigid.

Advantages

- It is adaptable to any quantity

- It creates high strength moulds & improves dimensional repeatability

- Requires low skill and labor requirements

- Provides better dimensional control.

Applications

- Ideal for high value and critical parts

- Desired for Complicated Profiles

|

| |

|

| |

|

|

End Cap Moulding Process Capability |

| Max Weight |

= 250 Kgs |

| Max Size |

= 2000 X 2000 mm |

| Minimum Wall Thickness |

= 4.5 mm |

| |

| |

| |

|

| |

|

| |

| |

No Bake Moulding Process Capability |

|

|

| Economical Order Quantity |

= 100 Number |

| Casting Tolerance |

= ± 0.75 mm |

| Minimum Wall Thickness |

= 4.5 mm |

| |

| |

| |

|

| |

|

| |

|

|

Aluminium Valve Body Moulding Process Capability |

| Surface Finish |

= 12 - 24 Microns |

| Minimum Core hole size |

= 10 mm |

| |

|

| |

| |

| |

|

|

HOME | ABOUT US | QUALITY CONTROL & SYSTEMS | INDUSTRIES WE SERVE | CONTACT | ENQUIRY

Copyright © 2011@ Aluminium Casting, Coimbatore, Web @ c-wavetech.com |